What are the types of indicators?

Indicator Devices inserted into packed set and attached to the outside of the wrapper/container to monitor sterilization exposure conditions.

Sterilization indicators are tools used to verify the effectiveness of a sterilization process. They are important in ensuring that medical equipment, instruments, and supplies are free from harmful microorganisms, and are safe to use on patients. There are several types of sterilization indicators, including:

1. Biological Indicator

2. Chemical Indicator

3. Mechanical Indicator

Biological indicators (BIs): These are the most accurate type of sterilization indicators and are used to monitor sterilization processes that utilize heat, such as autoclaving. They contain spores of heat-resistant bacteria that are killed when the sterilization process is successful. BIs are often used in healthcare settings to ensure that medical equipment and instruments are properly sterilized.

The biological microorganism used in steam sterilizers is Geobacillus stearothermophilus. The biological microorganism used for ETO is Bacillus atrophaeus / Geobacillus subtilis. The biological indicator is placed in the most difficult area in the autoclave for the sterilant to reach Incubation period is 48 hours.

A biologic indicator is a preparation of living endospores that are resistant to the sterilizing agent. The preparation may be supplied in a self contained system (e.g., dry endospore strips) or in sealed vials or ampules of endospores in suspension.

How to perform biological indicator test?

To perform the test, a biologic unit that has been exposed to the sterilant and an unprocessed biologic unit (control) from the same lot number are incubated for the same period of time. If sterilization has occurred, the processed biologic unit will not grow any microorganisms. The unprocessed biologic control unit will grow microorganisms and display a change in color. If the unprocessed biologic unit fails to grow microorganisms, its endospores have been inactivated. In such a case, the processed unit also may have been inactive before processing; thus the biologic test is rendered invalid. The entire load is considered unsterile when either the test indicator or the control is in question. Test indicators and controls should be interpreted by qualified personnel. The enzyme in the biological indicator will turn a fluorescent yellow within 60 minutes as the endospores are killed.

Chemical indicators (CIs): These are used to monitor various types of sterilization processes, including steam, ethylene oxide (ETO), and hydrogen peroxide gas plasma. They change color when exposed to a specific temperature or gas, indicating that the sterilization process has occurred. CIs are often placed on the outside of packaging materials to confirm that the contents have been sterilized.

Chemical indicators Autoclave tape on the outside of wrapped items (tape changes colors when exposed to the sterilant and temperature). Steam sensitive tape is tan and reveals dark stripes when exposed to steam sterilization. Gas sensitive tape is light green and reveals dark stripes when exposed to gas sterilization. Internal steam indicators are placed on the inside of the instrument sets. Rigid containers have a plastic indicator that is attached to the outside locking devices; a black dot appears when exposed to the sterilant and temperature.

Categories of Chemical Indicator:

Chemical indicators are categorized into classes according to the type of process measurement they perform.

• Class 1: Immediate visual indicator on the exterior of the processed pack, such as striped tape or a tab that changes color in response to the sterilizer.

• Class 2: Autoclave test packs used to test for air removal during the cycle.

• Class 3: Single-variable indicator of one of the parameters of sterilization.

• Class 4: Multivariable monitor strip that displays two or more changes in response to sterilization. Commonly used in a dry heat cycle.

• Class 5: Chemical integrator strip that reacts in the same way as a biologic indicator in the presence of time, temperature, and steam penetration.

• Class 6: Emulating indicator responds to all critical variables .during the use of a sterilization process challenge pack/process challenge device (PCD).

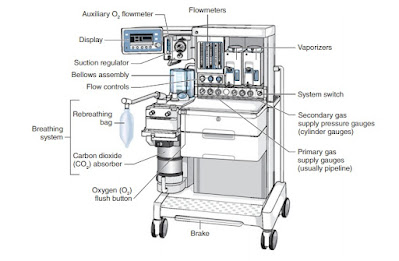

Mechanical indicators (MIs): These are used to verify that the sterilization process has occurred by checking that certain physical conditions have been met, such as temperature and pressure. MIs are often used. The mechanical indicators simultaneously measure and visualize the speeds of rotating objects. They are connected directly to the point of movement via a shaft and need no power supply.