Anesthesia Equipment Maintenance and Calibration Procedures

Anesthesia equipment checking and calibration are crucial steps in ensuring the safety and effectiveness of medical procedures in the operating theater.

Here's a step-by-step explanation:

Preparation:

Gather the necessary tools and documentation, including calibration certificates, user manuals, and any specific checklists provided by the equipment manufacturer.

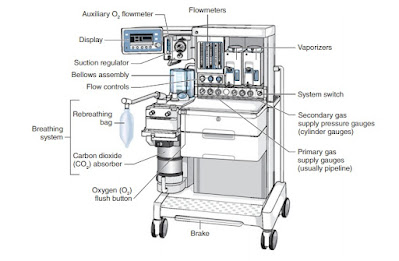

Visual Inspection:

Examine the anesthesia workstation for any visible damage, loose connections, or signs of wear. This includes checking hoses, cables, and the physical condition of the equipment.

Power-Up Test:

Turn on the anesthesia machine and associated equipment to ensure proper power-up sequences. Verify that all components, such as monitors and ventilators, initiate without errors.

System Check:

Perform a system self-test if available. This test helps identify any internal malfunctions within the anesthesia machine.

Gas Supply Verification:

Confirm the availability of medical gases and check the pressure levels. Ensure that the pressure regulators are functioning correctly.

Ventilator Calibration:

Calibrate the ventilator to ensure accurate tidal volume delivery, respiratory rate, and other parameters. Use a calibrated test lung to verify the ventilator's performance.

Gas Flow and Vaporizer Calibration:

Calibrate the flow meters to guarantee accurate gas delivery rates. Check and calibrate vaporizers for volatile anesthetics to ensure precise administration.

Oxygen Analyzers:

Calibrate and verify the accuracy of oxygen analyzers. Confirm that the concentration of inspired oxygen is within the specified range.

Pressure Monitoring:

Calibrate pressure monitoring devices, including those for airway pressure, PEEP (positive end-expiratory pressure), and other relevant parameters.

Temperature and Humidity Control:

Ensure that the temperature and humidity control systems, if present, are functioning properly to maintain a suitable environment for the equipment.

Alarms Testing:

Test and verify the proper functioning of alarms, including high and low pressure, low oxygen concentration, and any other alarms specified by the equipment.

Documentation:

Record the results of the checks and calibrations in a log or checklist. Include details such as date, time, equipment condition, and any corrective actions taken.

Regular Maintenance:

Establish a routine maintenance schedule for the anesthesia equipment based on the manufacturer's recommendations. Regularly check and update calibration records.

Staff Training:

Ensure that the healthcare personnel operating the anesthesia equipment are trained on proper usage, checks, and emergency procedures.

Regular and thorough anesthesia equipment checking and calibration are essential to maintain patient safety and the overall effectiveness of medical procedures in the operating theater. It also helps in compliance with regulatory standards and ensures that the equipment functions as intended.